- HOME

-

PRODUCTS

- Tool cabinet

- Tool set

- Hand Tool

- Working Light

- Power Tools

- Pneumatic Tools

- Hose Reel

- Hydraulic Tools

- Welding and Cutting Machine

- Industrial Power & Cleaning Equipment

-

Automotive Tools

- Engine Service Tools

- Engine Timing Tools

- Transmission Tools

- Steering/Suspension

- Brake tools

- Electrical/Electronic Tool

- Body & Interior Tools

- Inspection/Diagnostic/Calibration Tools

- Oil & Fluid Tools

- AC Tools

- Tire & Wheel Tools

- Exhaust System Tools

- Rescue/Safety Tools

- General/Universal Tools

- Consumables & Assortment Kits

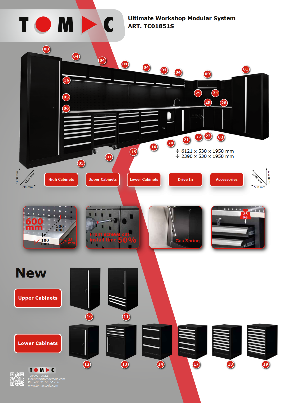

- TOMAC

- DOWNLOAD

- NEWS

- CONTACT

- ABOUT US

- BLOG

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

IW

IW

GA

GA

MI

MI