Why Rolling Cabinets Transform Garage Organization

Maximizing Mobility for Flexible Workspaces

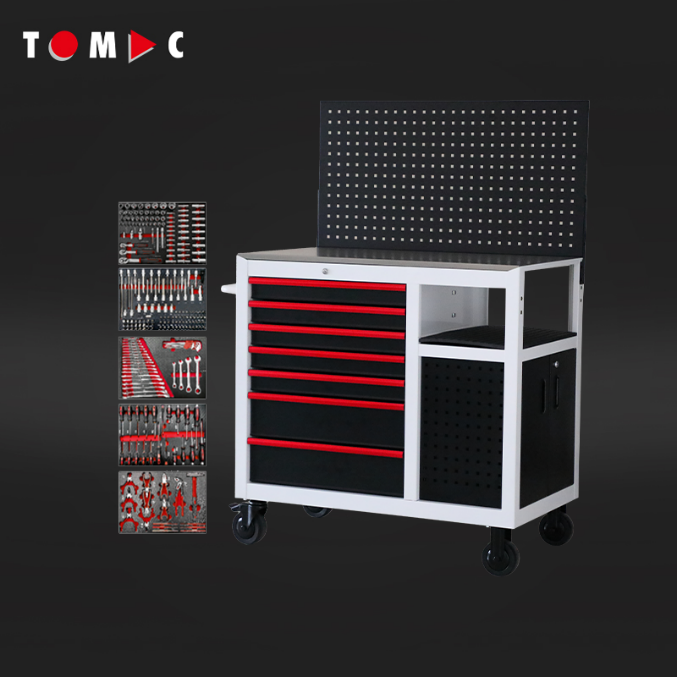

Rolling tool cabinets provide excellent mobility, letting you migrate tools and equipment around your area as needed. This flexibility can be crucial in a garage where everything from projects, to car repair, require accessibility and versatility. Rolling cabinets Let you travel with your automotive tool set and automotive tools for alignment throughout your shop or to and from your home garage with ease for a smoother work process. This flexible system not only frees up your workspace, but can allow for more productivity by cutting down the time it takes to search for tools and equipment. In the end, rolling cabinets are an essential to turning any flexible workspace into an efficient one.

Space Efficiency Compared to Fixed Storage

Rolling storage provides a more versatile solution to the problem of any floor accumulation than fixed cabinets or limitlessly adaptable wall tracks. They maximize the space you have through creating flexibility for reorganization as your needs change. Fixed storage can take up a lot of space, it's never in the right place and sometimes it isn't there when you need it – which results in more back and forth trips to get your tools to where you need them and they can waste valuable time and space.Harbor Freight has the solution not only for better storage, but for a rollout workspace as well! If you are as dedicated to maintaining an efficient work space, consider thinking outside the box with a rolling cabinets that provides the right mix of storage and mobility to meet your demands. But these units also store a wide variety of items from automotive tool boxes to large and heavy accessories and gear–even bulk food items! By adding rolling cabinets, you can make your garage easy to navigate and suitable for any new projects or adjustments of storage needs.

Planning Your Garage Layout for Rolling Cabinet Integration

Assessing Current Storage Pain Points

The first step to a successful rolling cabinet implementation in your garage is determining what frustrations you currently have with storage. Productivity can be hindered by complications like hard to reach tools and messy work areas. By assessing the usage of certain tools, such as the 'Automotive tool box', you will be able to make more informed decisions on placement in your garage. Use the tools that you use and need the most to be as efficient as possible. Furthermore, if you take the time to visually document these pain points e.g. with block diagrams or sketches, you will also get a good overview of your current situation, which can help you more strategically organize your tools after the integration.

Mapping High-Traffic Zones and Cabinet Placement

Then, having a complete plan of the space is crucial to make sure that rolling cabinets will improve your process, not complicate it. Start by shading the high-traffic areas—places where you move a lot. This gives you the chance to strategically place cabinets to ease operations so that tools, even non-standard ones such as auto alignment tools, are quickly available. You can easily study your garage using measuring tools and materials. Further, using mapping software or apps may improve the accuracy of your layout, so that you design a system that gives you ready access to most areas. This thoughtful preparation helps to keep your garage working well and organized.

Choosing Optimal Rolling Cabinets for Automotive Tools

Critical Features: Weight Capacity and Durability

When choosing rolling cabinet for car tools, make sure they can carry a heavy load. This becomes very important when you are storing something very heavy such as an automotive tool box, as it can cause damage to the tools and to the cabinet. (2) Durable Material Cabinets Strong and sturdy cabinets that will last Free standing cabinets.Cabinets that are ideal in a garage, for storing items and protecting them from garage conditions. You can verify the above claim by checking online reviews by customers or the manufacturer’s description of the cabinets, which may also have information that can tell you about the resilience of the cabinets. In the end, choosing the best garage cabinet for you will depend on a mix of durability and longevity to handle the demanding work in your garage.

Modular Systems vs. Standalone Units

Comparing modular vs standalone systems is crucial in deciding which is the best type of storage for your tools. Modular layouts are flexible and expandable, allowing room for growth in your tool collection. And thanks to its scalability, you can tack on additional units, like side cabinets or hutches, if your requirements evolve. Across them, standalone models are probably the least expensive and most straightforward in terms of installation, unless, of course, you find yourself with a situation where an extra couple of terabytes are required. Choose a product based on the type of automotive repair tools that you have and want to keep, whether being more versatile or easier to use.

Security Considerations for Valuable Tools

When purchasing rolling cabinets to store valuable automotive tools, security is an important factor to consider. When doors are impossible to lock on cabinets, it just becomes too easy for others to steal or abuse your investment. Also, you should look at your garage layout and decide what you can see and access from the outside and where the entry points for unwanted visitors are that will allow you to keep your tools more safe. If you opt for cabinets that balance access for daily use with strong security features, you will have the reassurance that your hi-tech automotive alignment kit tools and any other expensive equipment are safe and secure.

Organizational Strategies for Rolling Cabinet Success

Categorizing Automotive Tool Kits and Accessories

A well-organized automotive tool kit in a rolling cabinet involves logical categorization. By breaking down tools according to their function or type we’ll speed up the clean up process and increase productivity. Kits can also be sorted by use, with the items used most often in the cabinet at eye level. Not only does this save time, it encourages good maintenance. To go a little a further in terms of usability, color selected bins or labels (color-coded) visually separates sections and simplifies location in our automotive tool kits.

Vertical Storage for Impact Driver Bit Sets

A good way to maximize cabinet space is to use our vertical storage bins, magnetic strips or pegboards for our impact driver bit sets. The way the mugs hang allow for additional space saving storage in your cabinets. Our vertical storage solution is perfect for identifying tools easily and getting the job done fast while keeping your tools in organized. We can have a lot more fun working in the garage by designing storage for impact driver bits sets.

Labeling Systems for Quick Identification

Streamlining the workflow in a crowded garage is only possible with a structured labeling process in place. Use of type label makers, or pre-printed labels looks professional and equipment can be read which is critical for fast identification of tools. Images on labels can also be added to expedite learning and product recognition for a variety of learners. This idea contributes to our organisation policy that keeps the workspace clear and tidy.

Maintenance and Accessibility Best Practices

Routine Reorganization Workflows

Having a regular rotation process of the reorganized items is a must to keep the rolls accessible and in order. Any way you choose to do it, by creating some kind of schedule, such as monthly, or when a tool breaks, you can go through a round of removing old or non-working tools viable for replacement. Not only does this system encourage the efficient use of space, but it prevents mislaid tools. Furthermore, by promoting team members to engage in these habits, you can create sensitivity for organization and discipline, hence a more sound work environment. Gain streamlined processes and boosted productivity—from reorganizations to daily tasks. Dry-brushing these basic matters is, hence, a helpful maintenance to all.

Seasonal Adjustments for Automotive Repair Tools

It all depends on how you store and arrange auto repair tools, and seasonal changes make a world of difference in how easily those tools can be located and put to use. We can locate project or seasonal-specific tools and we can then re-determine how and where we keep things in the cabinet. This method means the most regularly used tools are easily to hand, and there is somewhere useful for the less often used tools to be kept safe and sound. Making a few seasonal changes allows us to start each season with a fresh and orderly space. On the level of the users, this results in us being able to easily and very efficiently manage our tools, increasing our work efficiency, and the condition of the tools we have.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

IW

IW

GA

GA

MI

MI